In recent years it has become “fashionable” for MNCs to expand their activities in some part of freight transport, such as maritime transport. They create integrated systems that cover the entire length of shipping from the production site to the final customer. The time-based method of calculating the company’s added value (time-based analysis) shows how this can waste the resources of the manufacturer, the supplier and the customer.

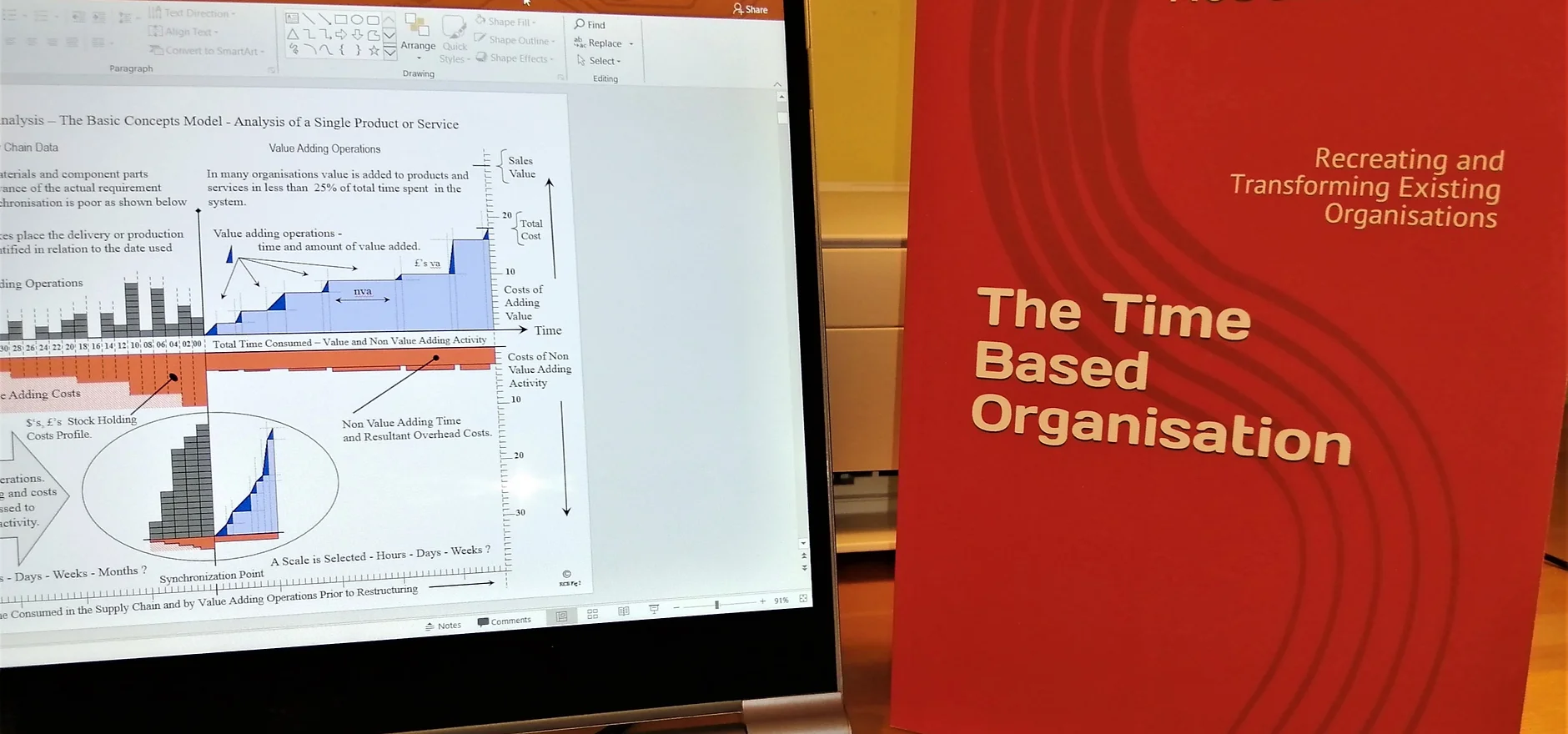

Time-based analytics have shown that manufacturing a product or providing a service typically adds a value in only 15 percent of the total time from start to finish (If this period is, let’s say, 100 days, then in 15 days only.) For British government institutions, this ratio is only 4 percent. This poor efficiency suggests that a major part of the time is a waste, writes dr. Bob Barker, author of Time Based Organization – Recreating and Transforming Existing Organizations.

Barker reports on his experience at large companies in an internet post. Working for them, he tried for years to make the “push” distribution system of the enterprise management systems (ERP/MRP) in a way that would have been expected and would have met the needs of the companies’ managers and customers.

At an American company in the 1980s, he listened until he was brainwashed that modern companies are unthinkable without these systems. Compared to this, as the years went by, product stocks kept growing, used warehouse space expanding, orders delayed, and customer service complaints increased.

ERP systems cost companies billions of dollars, but the debate was only about which algorithms were the best.

The company he worked for naturally did not want to part with their resource planning system. Therefore, Barker decided to change the “push” principle to the “pull” distribution method by modifying ERP. This resulted in a 60 percent reduction in stocks in a short period of time. That’s why he says that the basic principle of the time-based organization is in general an operation which is based on “pull” principle.

Time-based analysis shows a difference.

The “push” production management system is based on expected order data. Determines purchases based on the sales plan. In this way, stocks can accumulate on both the input and output side. Disruption of supply chains can be a big problem, and sales prices are affected by the size of finished product stocks. This method is suitable for predictable, large, technology-intensive companies based on mass purchases. The disadvantage is that you have to manage large stocks and the lead times are relatively inflexible.

The “pull” principle creates a direct link between orders and production or service. Companies that follow this principle produce from what they have on stock, or adapt their services to what they receive an order for. The logistics service provider can not only track the orders for adjusting deliveries in due time, but may also examine stock of products waiting to be sold on the shelf, in order to replace the sold products when they are still available to the customer. Thus, the supply is based on specific orders, i.e. it is suitable for smaller companies working with customers who shoot smaller batches. The rotation speed of the products is higher and the turnaround time of the products is shorter.

The time-based analysis of the company’s added value reveals that, given the cost and delivery fee, the supplier can increase the added value of its service per day if it fulfills the order in the shortest possible time. This is also one of the most important aspects of the customer and the logistics service provider capable of flexible operation.

This secret of the efficiency of corporate operations is lost under the mountains of data and sets of indicators of large companies. However, smaller companies can see what’s going on. Another argument against the expansion of MNCs in shipping industry.

Source of cover image: drbobbarker.co.uk

logmaster warehouse services

For our customers in Hungary and in the European Union we have about 1000 pallets warehouse space installed for temporary storage in our bonded warehouse near Budapest.

We offer value added services at our customs yard, shipment building for just in time, B2C or B2B deliveries to any Hungarian or any other destination in the EU.

For inquiries pls contact our experts, we are glad to provide you further information.